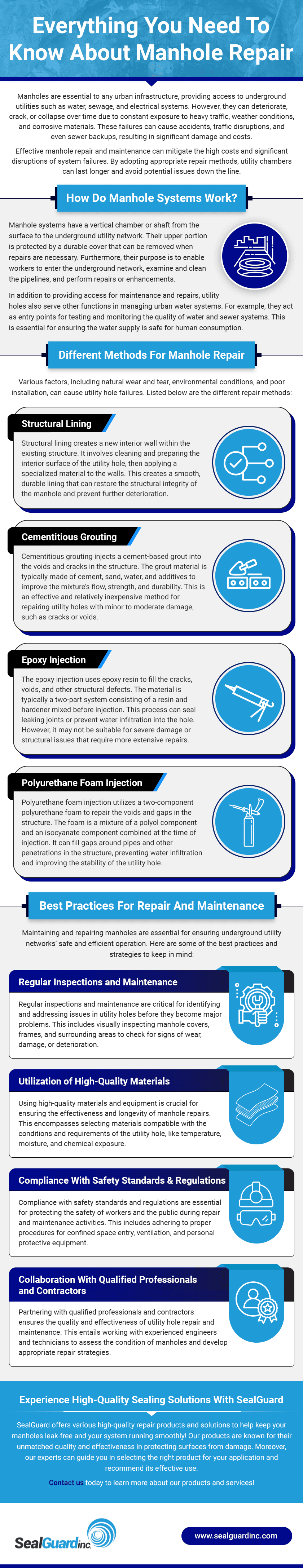

Manholes are essential to any urban infrastructure, providing access to underground utilities such as water, sewage, and electrical systems. However, they can deteriorate, crack, or collapse over time due to constant exposure to heavy traffic, weather conditions, and corrosive materials. These failures can cause accidents, traffic disruptions, and even sewer backups, resulting in significant damage and costs.

Effective manhole repair and maintenance can mitigate the high costs and significant disruptions of system failures. By adopting appropriate repair methods, utility chambers can last longer and avoid potential issues down the line. This article will discuss the key aspects of manhole repair, such as the different methods available and best practices.

How Do Manhole Systems Work?

Manhole systems have a vertical chamber or shaft from the surface to the underground utility network. Their upper portion is protected by a durable cover that can be removed when repairs are necessary. Furthermore, their purpose is to enable workers to enter the underground network, examine and clean the pipelines, and perform repairs or enhancements.

In addition to providing access for maintenance and repairs, utility holes also serve other functions in managing urban water systems. For example, they act as entry points for testing and monitoring the quality of water and sewer systems. This is essential for ensuring the water supply is safe for human consumption.

Different Methods for Manhole Repair

Various factors, including natural wear and tear, environmental conditions, and poor installation, can cause utility hole failures. Listed below are the different repair methods:

Structural Lining

Structural lining creates a new interior wall within the existing structure. It involves cleaning and preparing the interior surface of the utility hole, then applying a specialized material to the walls. This creates a smooth, durable lining that can restore the structural integrity of the manhole and prevent further deterioration.

Cementitious Grouting

Cementitious grouting injects a cement-based grout into the voids and cracks in the structure. The grout material is typically made of cement, sand, water, and additives to improve the mixture’s flow, strength, and durability. This is an effective and relatively inexpensive method for repairing utility holes with minor to moderate damage, such as cracks or voids.

Epoxy Injection

The epoxy injection uses epoxy resin to fill the cracks, voids, and other structural defects. The material is typically a two-part system consisting of a resin and hardener mixed before injection. This process can seal leaking joints or prevent water infiltration into the hole. However, it may not be suitable for severe damage or structural issues that require more extensive repairs.

Polyurethane Foam Injection

Polyurethane foam injection utilizes a two-component polyurethane foam to repair the voids and gaps in the structure. The foam is a mixture of a polyol component and an isocyanate component combined at the time of injection. It can fill gaps around pipes and other penetrations in the structure, preventing water infiltration and improving the stability of the utility hole.

Best Practices for Repair and Maintenance

Maintaining and repairing manholes are essential for ensuring underground utility networks’ safe and efficient operation. Here are some of the best practices and strategies to keep in mind:

Regular Inspections and Maintenance

Regular inspections and maintenance are critical for identifying and addressing issues in utility holes before they become major problems. This includes visually inspecting manhole covers, frames, and surrounding areas to check for signs of wear, damage, or deterioration.

Utilization of High-Quality Materials

Using high-quality materials and equipment is crucial for ensuring the effectiveness and longevity of manhole repairs. This encompasses selecting materials compatible with the conditions and requirements of the utility hole, like temperature, moisture, and chemical exposure.

Compliance With Safety Standards and Regulations

Compliance with safety standards and regulations are essential for protecting the safety of workers and the public during repair and maintenance activities. This includes adhering to proper procedures for confined space entry, ventilation, and personal protective equipment.

Collaboration With Qualified Professionals and Contractors

Partnering with qualified professionals and contractors ensures the quality and effectiveness of utility hole repair and maintenance. This entails working with experienced engineers and technicians to assess the condition of manholes and develop appropriate repair strategies.

Experience High-Quality Sealing Solutions With SealGuard

SealGuard offers various high-quality repair products and solutions to help keep your manholes leak-free and your system running smoothly! Our products are known for their unmatched quality and effectiveness in protecting surfaces from damage. Moreover, our experts can guide you in selecting the right product for your application and recommend its effective use.

Contact us today to learn more about our products and services!