Water intrusion can cause serious structural damage to buildings, leading to costly repairs and potential safety hazards. That’s why selecting an effective water sealing solution is crucial for any construction project.

Precast concrete structures have low permeability rates, which means they can effectively prevent water intrusion and provide reliable and durable sealing. Moreover, they are a sustainable choice for environmentally conscious builders as they can be constructed from recycled materials.

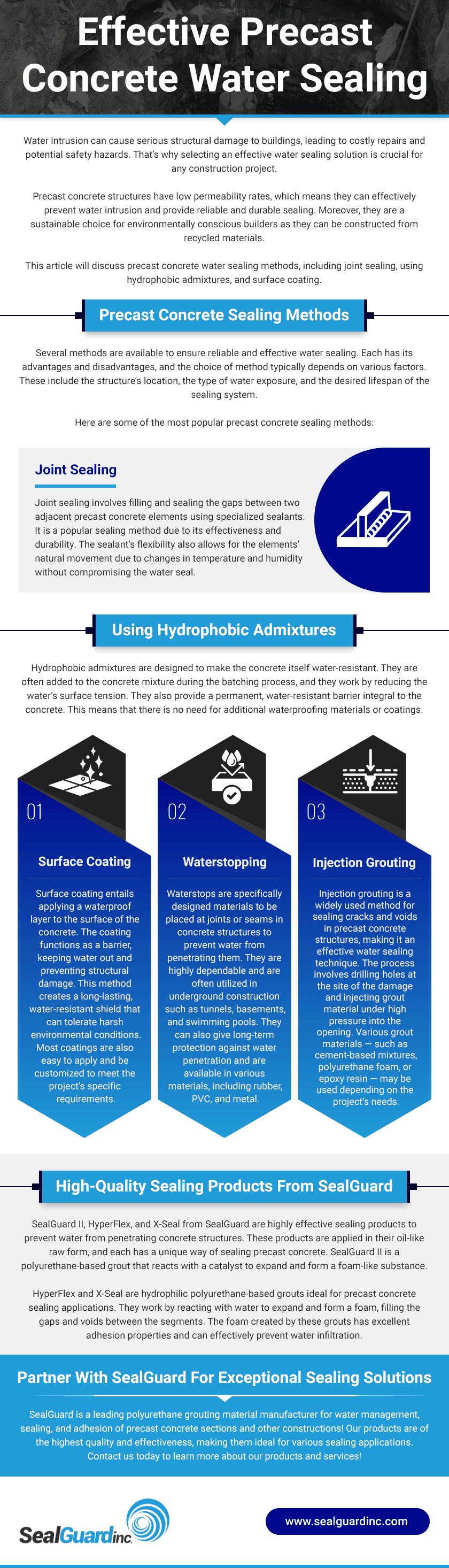

This article will discuss precast concrete water sealing methods, including joint sealing, using hydrophobic admixtures, and surface coating.

Precast Concrete Sealing Methods

Several methods are available to ensure reliable and effective water sealing. Each has its advantages and disadvantages, and the choice of method typically depends on various factors. These include the structure’s location, the type of water exposure, and the desired lifespan of the sealing system.

Here are some of the most popular precast concrete sealing methods:

Joint Sealing

Joint sealing involves filling and sealing the gaps between two adjacent precast concrete elements using specialized sealants. It is a popular sealing method due to its effectiveness and durability. The sealant’s flexibility also allows for the elements’ natural movement due to changes in temperature and humidity without compromising the water seal.

Using Hydrophobic Admixtures

Hydrophobic admixtures are designed to make the concrete itself water-resistant. They are often added to the concrete mixture during the batching process, and they work by reducing the water’s surface tension. They also provide a permanent, water-resistant barrier integral to the concrete. This means that there is no need for additional waterproofing materials or coatings.

Surface Coating

Surface coating entails applying a waterproof layer to the surface of the concrete. The coating functions as a barrier, keeping water out and preventing structural damage. This method creates a long-lasting, water-resistant shield that can tolerate harsh environmental conditions. Most coatings are also easy to apply and be customized to meet the project’s specific requirements.

Waterstopping

Waterstops are specifically designed materials to be placed at joints or seams in concrete structures to prevent water from penetrating them. They are highly dependable and are often utilized in underground construction such as tunnels, basements, and swimming pools. They can also give long-term protection against water penetration and are available in various materials, including rubber, PVC, and metal.

Injection Grouting

Injection grouting is a widely used method for sealing cracks and voids in precast concrete structures, making it an effective water sealing technique. The process involves drilling holes at the site of the damage and injecting grout material under high pressure into the opening. Various grout materials — such as cement-based mixtures, polyurethane foam, or epoxy resin — may be used depending on the project’s needs.

High-Quality Sealing Products From SealGuard

SealGuard II, HyperFlex, and X-Seal from SealGuard are highly effective sealing products to prevent water from penetrating concrete structures. These products are applied in their oil-like raw form, and each has a unique way of sealing precast concrete. SealGuard II is a polyurethane-based grout that reacts with a catalyst to expand and form a foam-like substance.

HyperFlex and X-Seal are hydrophilic polyurethane-based grouts ideal for precast concrete sealing applications. They work by reacting with water to expand and form a foam, filling the gaps and voids between the segments. The foam created by these grouts has excellent adhesion properties and can effectively prevent water infiltration.

Partner With SealGuard for Exceptional Sealing Solutions

SealGuard is a leading polyurethane grouting material manufacturer for water management, sealing, and adhesion of precast concrete sections and other constructions! Our products are of the highest quality and effectiveness, making them ideal for various sealing applications. Contact us today to learn more about our products and services!