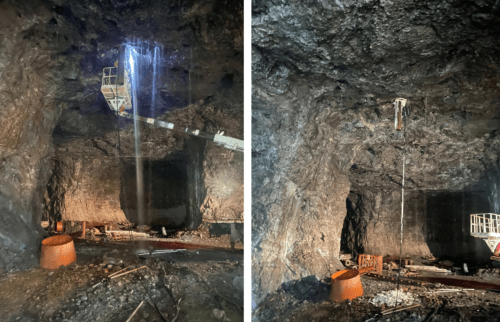

Single Component Polyurethane Grout Injection

Leave a CommentSmaller water leaks in structures can be sealed by injecting single component polyurethane grout into the leak paths. The grout being used is Hyperflex, manufactured by SealGuard, Inc. Being a single component grout, Hyperflex is pre catalyzed and only needs 2% moisture to start reacting (foaming). The expanding foam will fill the voids that is creating the leak. Once cured, the foam will remain flexible to allow for slight movements within the structure. The benefit of a single component grout is the slower reaction and lower viscosity. This allows the material to travel further before the reaction, allowing for better penetration and coverage within the leaking substrate. Hyperflex is also NSF/ANSI/CAN 61 approved for contact with potable water. This injection was done using a grout pump and mechanical injection packers. Burlap was placed in a large void before injection to help prevent the grout from washout. Grouting was performed by Sub-Technical, Inc.