Joining and Sealing Precast Concrete

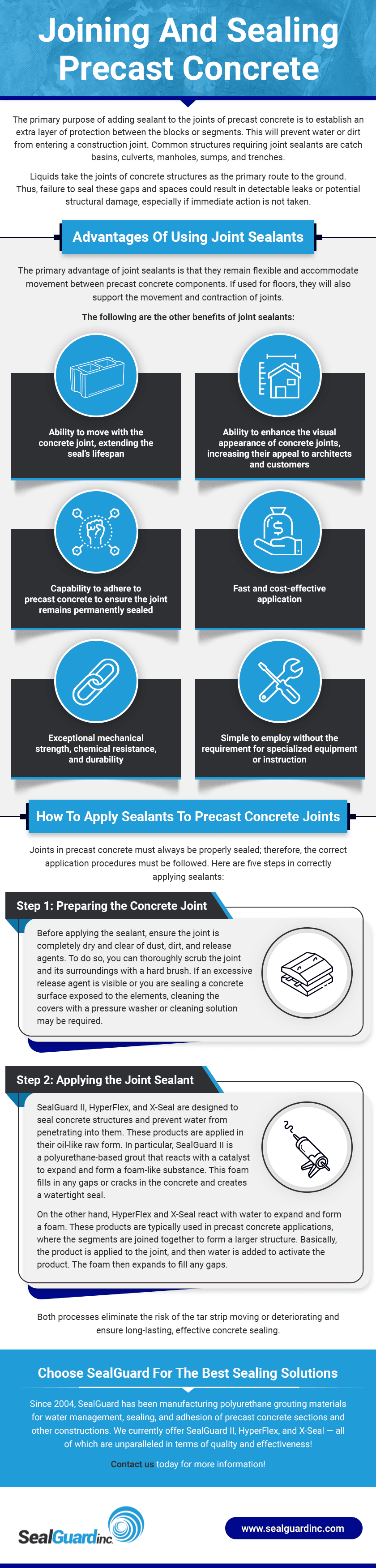

Leave a CommentThe primary purpose of adding sealant to the joints of precast concrete is to establish an extra layer of protection between the blocks or segments. This will prevent water or dirt from entering a construction joint. Common structures requiring joint sealants are catch basins, culverts, manholes, sumps, and trenches.

Liquids take the joints of concrete structures as the primary route to the ground. Thus, failure to seal these gaps and spaces could result in detectable leaks or potential structural damage, especially if immediate action is not taken.

This article will discuss the advantages of joint sealants for precast concrete and the application process.

Advantages of Using Joint Sealants

The primary advantage of joint sealants is that they remain flexible and accommodate movement between precast concrete components. If used for floors, they will also support the movement and contraction of joints.

The following are the other benefits of joint sealants:

- Ability to move with the concrete joint, extending the seal’s lifespan

- Ability to enhance the visual appearance of concrete joints, increasing their appeal to architects and customers

- Capability to adhere to precast concrete to ensure the joint remains permanently sealed

- Fast and cost-effective application

- Exceptional mechanical strength, chemical resistance, and durability

- Simple to employ without the requirement for specialized equipment or instruction

How To Apply Sealants to Precast Concrete Joints

Joints in precast concrete must always be properly sealed; therefore, the correct application procedures must be followed. Here are five steps in correctly applying sealants:

Step 1: Preparing the Concrete Joint

Before applying the sealant, ensure the joint is completely dry and clear of dust, dirt, and release agents. To do so, you can thoroughly scrub the joint and its surroundings with a hard brush. If an excessive release agent is visible or you are sealing a concrete surface exposed to the elements, cleaning the covers with a pressure washer or cleaning solution may be required.

Step 2: Applying the Joint Sealant

SealGuard II, HyperFlex, and X-Seal are designed to seal concrete structures and prevent water from penetrating into them. These products are applied in their oil-like raw form. In particular, SealGuard II is a polyurethane-based grout that reacts with a catalyst to expand and form a foam-like substance. This foam fills in any gaps or cracks in the concrete and creates a watertight seal.

On the other hand, HyperFlex and X-Seal react with water to expand and form a foam. These products are typically used in precast concrete applications, where the segments are joined together to form a larger structure. Basically, the product is applied to the joint, and then water is added to activate the product. The foam then expands to fill any gaps.

Both processes eliminate the risk of the tar strip moving or deteriorating and ensure long-lasting, effective concrete sealing.

Choose SealGuard for the Best Sealing Solutions

Since 2004, SealGuard has been manufacturing polyurethane grouting materials for water management, sealing, and adhesion of precast concrete sections and other constructions. We currently offer SealGuard II, HyperFlex, and X-Seal — all of which are unparalleled in terms of quality and effectiveness!

Contact us today for more information!